Energy Management System Solutions

Reduce energy consumption, improve system utilization, increase reliability, predict electrical system performance,

and optimize energy usage with an advanced Energy Monitoring System to lower costs.

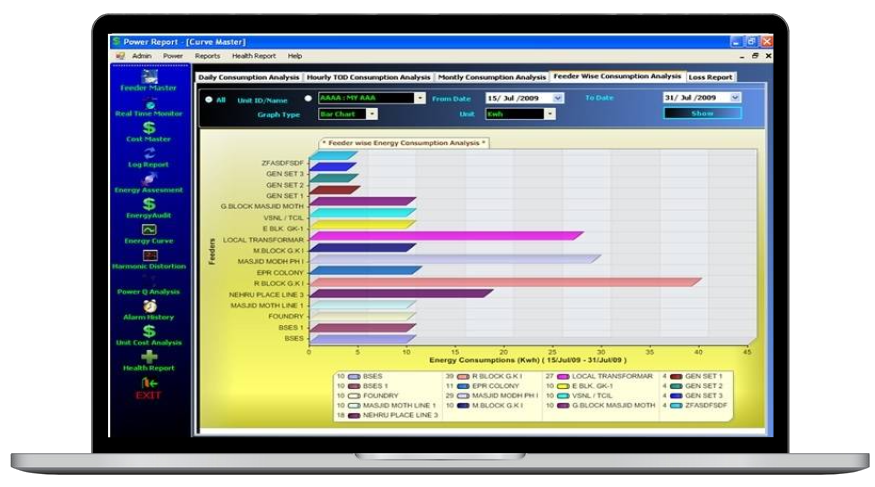

Comprehensive Platform for Energy Management System

Our Energy Logic- Energy Management System (EMS) platform makes energy data simple to acquire, understand and act upon. Energy Logic is a Plug and Play platform and can be implemented in the existing system at a very cost effective price. Every plant or facility wastes energy in hundreds of places and processes. We help you identify this wastage and reduce it. Our energy management solution helps you reduce financial and environmental impact of wasteful energy consumption by effectively managing energy use and the factors that affect it. We help both small and large organizations in measuring, analyzing and reducing energy costs by up to 30%.

Business Solutions to Industries

With our energy management experts, implementing energy management in your facility is easy and quick. As one of India's leading Energy Monitoring System companies, we provide the following services as part of the industrial energy management system solution:

- Data Acquisition- Data monitoring of all electrical parameters for all feeders, incomers, DG set

- Real-time energy data monitoring

- Energy accounting – Sectional, feeder, department-wise

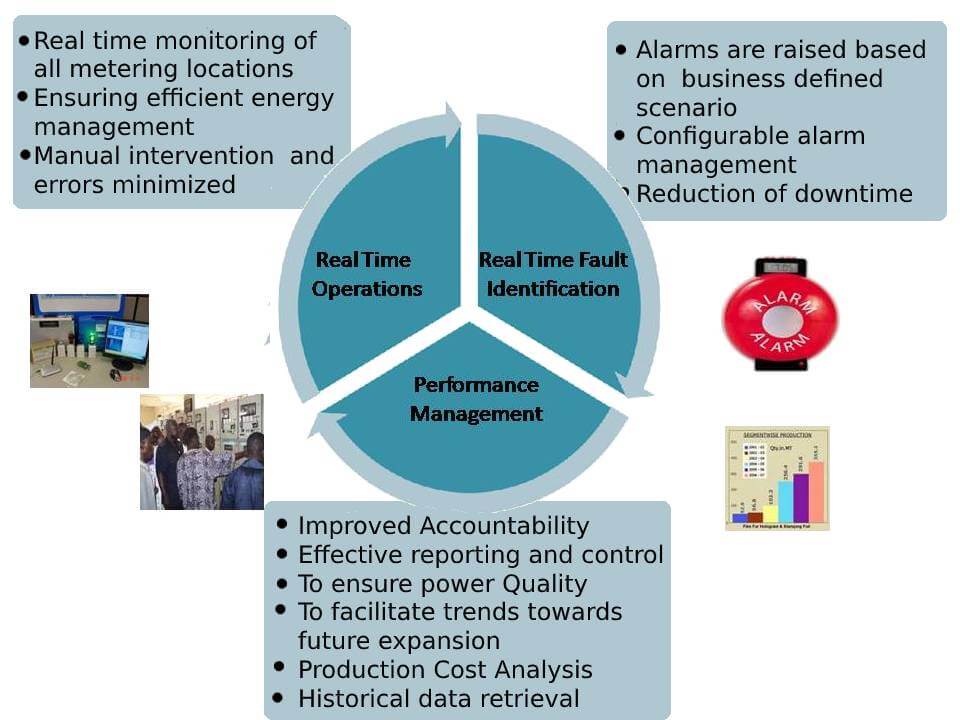

- Online Alarms

- Demand Management

- Performance Management

- System Health

- Advanced Data Analytics

- Utility Bill Verification

- Production Cost Analysis

- Improved accountability

- Exception Reporting

- Industrial energy management system

Continuous Targeting & Optimization Services

We help you continuously improve and reduce energy consumption with our advanced Energy Monitoring System through:

- Data Acquisition- Monitoring all electrical parameters for feeders, incomers, and DG sets

- Data Analysis – Analyzing your data to identify energy wastage

- Data Comparing - Comparing energy consumption against appropriate standards or benchmarks

- Setting Targets - Establishing targets to reduce energy consumption

- Monitoring - Regularly comparing actual energy consumption to the set targets

- Reporting - Reporting results and any variances from targets

- Controlling - Implementing corrective measures for any deviations

Solution for All Sector & Technologies

- Air-Conditioning

- Chemical & Pharmaceutical industries

- Power Supply & Distribution

- Water & waste water Treatment

- Mechanical & plant Engineering

- Plastic & Rubber industries

- Paper manufacturing & processing, printing industries

- Metal process & steel industries

- Building control technology & Property management

Real-Time Energy Monitoring System for Maximum Efficiency

Our Energy Monitoring System offers a centralized, real-time view of energy consumption across your facility. Utilizing IoT-enabled sensors and cloud-based analytics, the system actually allows organizations to:

- Monitor Energy in Real-Time: Track usage of electricity across feeders, departments, or even machines instantly.

- Receive Smart Alerts: Get automated notifications via SMS, or email for anomalies, outages, or energy spikes.

- Optimize Energy Usage: Identity inefficiencies in processes and equipment, enabling corrective actions that really reduce costs and carbon footprint.

- Benchmark Performance: Compare energy consumption across departments or units in order to highlight underperforming areas.

- Data-Driven Decisions: Advanced analytics help management make informed decisions about energy procurement, maintenance, along with operational planning.

- Industry-Wide Application: Perfect for manufacturing, chemical, pharmaceutical, water treatment, and building management industries, and help each sector reduce energy waste while improving productivity.

Benefits of Implementing an Energy Monitoring System:

- Reduce energy costs by up to 30%

- Improve operational efficiency and system reliability

- Minimize environmental impact of wasted energy

- Enhance accountability through detailed reporting and analysis

By integrating a strong Energy Monitoring System, your facility can shift from reactive energy management to proactive, data-driven optimization, ensuring sustainable growth and measurable savings.