25/02/2026

Blogs

What is Solar Monitoring and Why Every Solar Plant Needs It?

What is Solar Monitoring and Why Every Solar Plant Needs It?

What is Solar Monitoring and Why Every Solar Plant Needs It?

Running a solar plant isn’t only about setting up panels and generating energy. Over and above that, it’s about knowing exactly how your system is performing at all times. Solar monitoring actually gives you real-time insights into energy production, identifies problems before they become costly issues, and helps improve overall efficiency.

In this guide, we’ll break down how solar plant monitoring actually works, the benefits it really brings, and various practical tips to implement it effectively, so that you can save money, prevent downtime, and ultimately get the most out of solar setups.

What is Solar Monitoring?

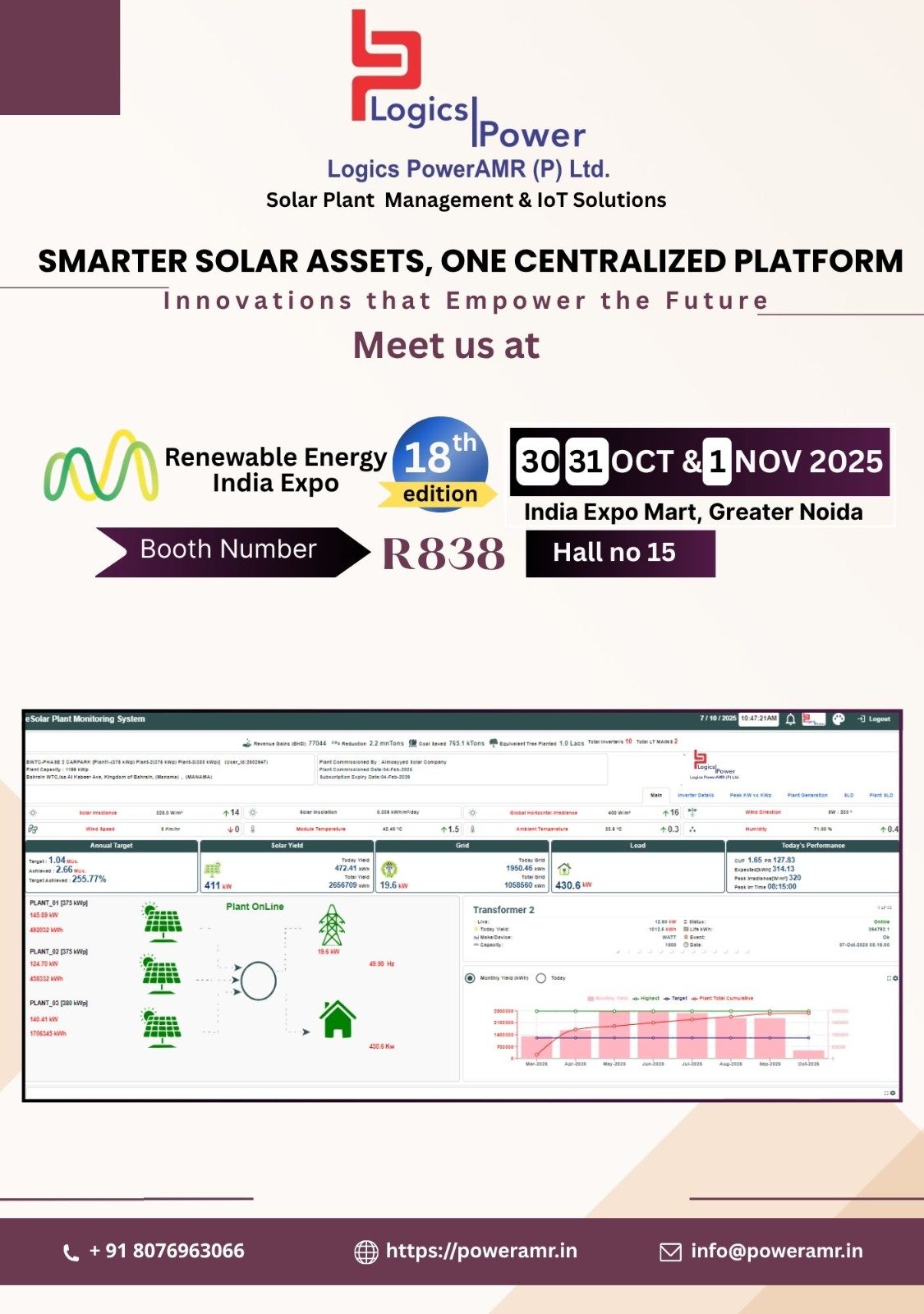

Solar monitoring is a process of real-time performance, power generation, and health monitoring of a solar power system. It actually gives useful insights to operators regarding the efficiency of how the system is working. Moreover, it detects different faults and poorly performing components, and eventually optimizes energy production.

Contrary to manual checks, it actually means that each of the panels and inverters is checked on-the-fly, and that active maintenance and data-driven decision-making are possible.

Traditional Monitoring vs Modern Digital Monitoring

-

Traditional Monitoring

Involves periodic manual inspection and meter readings. It’s really time-consuming, prone to human errors and mostly fails to detect issues until they actually cause significant energy loss.

-

Modern Digital Monitoring

Uses devices that can connect to the Internet of Things (IoT), automated data collection, as well as dashboards that are stored in the cloud. This really gives operators real-time insights, predictive alerts, and actionable analytics, which help them improve performance and cut down on downtime.

Components of a Solar Monitoring System

1. Sensors

Measure solar irradiance, panel temperature, and voltage/current in order to track performance at the component level.

2. IoT-Enabled Meters

Collect and transit data from solar panels, inverters, and meters to a central system for real-time analysis.

3. Web Portals / Dashboards: User-friendly interfaces that really show live performance data, energy production trends, and alerts from computer or mobile devices.

4. Data Analytics: Furthermore, these sensors process collected data in order to identify patterns, detect inefficiencies, predict failures, and give actionable insights for better decision-making.

5. Types of Monitoring:

-

Module-Level Monitoring: This one actually tracks the performance of each panel for granular insights.

-

String-Level Monitoring: Monitors a series of panels together, and it’s useful for medium to large installations.

- Plant-Level Monitoring: This gives an overview of the entire solar panel’s performance, perfect for industrial or commercial setups.

How Solar Monitoring Works

Solar monitoring converts raw energy data into actionable insights and allows operators to optimize performance and prevent costly downtime. Here’s a step-by-step breakdown of how exactly it works:

1. Data Collection from Sensors and Meters

Each solar panel and inverter has sensors and IoT-enabled meters that measure solar radiance, energy production, voltage, current, and panel temperature. Also, this information is always being collected, so there is no downtime or inefficiency that goes unnoticed.

2. Transmission to a Central System

Then, the data that has been collected is sent securely to a central monitoring system or cloud platform over wired or wireless networks. This lets you keep track of the whole solar plant in real time and manage it all from one place, whether it's a commercial rooftop or a large industrial setup.

3. Real-Time Analysis and Performance Tracking

After processing data that comes in, advanced analytics platforms compare it to performance benchmarks that are predicted. And, this analytics shows all inefficiencies, underperforming panels, or even deviations brought on by dirt, shade, or malfunctioning equipment.

4. Alerts and Notifications for Faults or Downtime

If any anomaly or even potential failures are identified, the system instantly sends alerts to operators through web dashboards, mobile applications, or email. These real-time notifications allow immediate corrective actions and reduce downtime and energy loss.

5. Visualization through Dashboards and Reports

Intuitive dashboards display energy production trends, efficiency metrics, and past performance. Operators can also generate detailed reports, track KPIs, and make data-driven decisions in order to their plant output.

6. Optional Integration with Other Systems

Modern solar monitoring can integrate with energy management systems (EMS), predictive maintenance tools, and weather monitoring stations for further performance enhancement insights and operational planning.

Benefits of Solar Monitoring

1. Operational Efficiency

Monitoring your solar system in real time actually ensures that every panel as well as the inverter, is performing well. And, continuous oversight helps detect underperformance quickly and maximize energy output and overall plant productivity.

2. Cost Reduction

Moreover, automated tracking reduces the requirement for manual inspection and minimizes energy losses that often take place by faults or downtimes. Ultimately, this leads to lower operational expenses and improved return on investment.

3. Maintenance Optimization

Predictive alerts instantly notify operators regarding potential issues before they even escalate, and enable proactive repairs. Now, this reduces emergency maintenance, extends the life of equipment, and prevents any unexpected production halts.

4. Data-Driven Decisions

Another benefit that operators get is detailed analytics. The detailed analytics provide insights into energy generation patterns, efficiency trends, and consumption behaviour. Operators can make informed choices that truly enhance profitability, dependency on the system, and long-term performance.

5. Regulatory Compliance & Reporting

Over and above that, automated monitoring tracks performance, generates audit-ready reports, ensures adherence to standards, supports sustainability goals, and helps operators make informed decisions and demonstrate system efficiency and reliability.

Trending Technologies in Solar Monitoring

-

IoT-enabled monitoring

-

AI and machine learning for predictive maintenance

-

Big Data analytics for performance optimization

-

Cloud dashboards & mobile apps

Real-Life Use Cases / Applications of Solar Monitoring

1. Performance Tracking

You can monitor the real-time energy output of each panel and inverter in order to ensure optimal system performance. Furthermore, it detects underperforming components quickly.

2.Energy Loss Detection

The system actually helps you identify energy losses often caused by things like shading, dirt on panels, or sometimes equipment inefficiencies. When you catch it early, you can take quick action and make sure your plant is running at its best.

3.Regulatory Compliance & Reporting

Monitoring tools automatically generate reports that are required for government, utility, or even sustainability standards. Now, this keeps you compliant and makes it much easier to provide clear documentation whenever needed.

4.ROI & Cost Optimization

By analyzing energy patterns and operational data, you can make smarter decisions that cut operational costs and ultimately improve the overall return on your solar investment.

5.Integration with Energy Management Systems

You can also connect your monitoring system with energy management tools, weather stations, along with predictive analytics. Now, this helps optimize the performance of your entire plant, all in one place.

Step-by-Step Implementation Guide

1. Assess Your Solar Plant Requirements

Start by understanding your system’s size, type of panels, inverters, and connectivity needs. Identify performance goals, reporting requirements, and regulatory standards.

2. Choose the Right Monitoring Solution

Choose IoT-based solar monitoring systems that include meters, sensors, and compatible software. Always make sure that dashboards and analytical tools complete the scale of your plan, small rooftop or even a large industrial installation.

3. Install Hardware and Connectivity

Set up sensors on panels and inverters. Ensure secure data transmission through wired or even wireless networks, so that you can track performance in real time.

4. Configure Software and Dashboards

Connect all meters and sensors to your monitoring platform, set up alerts, notifications, as well as reporting templates for easy access and proactive management.

5. Test and Calibrate the System

Now, verify data accuracy and real-time updates. And, calibrate sensors and meters in order to ensure reliable readings and meaningful insights.

6. Train Your Team

Educate your staff on using dashboards, analyzing trends, responding to alerts, and making data-driven decisions. A trained team can really maximize the value of monitoring.

Checklist of Tools & Infrastructure:

-

IoT-enabled meters and sensors

-

Web portals or cloud-based dashboards

-

Secure internet or private network connectivity

-

Analytics software and reporting tools

-

Backup power and data storage systems

Common Mistakes to Avoid:

-

Skipping proper sensor calibration

-

Choosing incompatible software

-

Ignoring predictive maintenance alerts

Conclusion

Solar monitoring is no longer an option. On top of that, it is necessary to increase efficiency, reduce downtime, and make data-driven decisions that can actually increase profitability.

The adoption of a powerful monitoring system by businesses will provide operators with real-time information, predictive indicators, and action-oriented analysis that will radically change how energy is handled. Despite the size, be it a small rooftop or even a large industrial plant, the benefits are real and quantifiable. To have bespoke, the best solar monitoring system that indeed optimizes performance, contact Logics PowerAMR to provide state-of-the-art technology and professional service.

24/02/2026

Zero Export Controller Explained:...

23/02/2026

Ambient Temperature Sensors vs...

19/02/2026

High-Precision Module Temperature Sensor...

28/01/2026